Young Innovators Present Solutions for Manufacturing Innovation Challenge

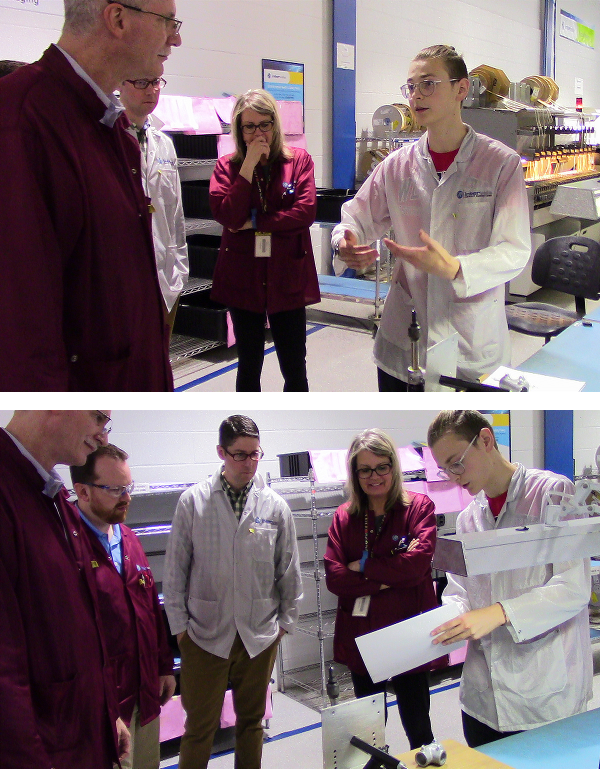

Students from Allderdice High School in Pittsburgh returned to Intervala before summer break to present their solutions for two real-life challenges in the company’s production processes. The young innovators were participants in Catalyst Connection’s Manufacturing Innovation Challenge program which brings together the brightest minds of tomorrow’s workforce with Southwestern Pennsylvania companies to engage in hands-on improvement projects.

The students first presented their design for a fixture that suspended a hand-held rivet gun used to place rivets on printed circuit boards. The tool can be cumbersome for employees to handle as it recoils and must be reset each time a rivet is placed on a board. The students created a fixture to stop the recoil action and allow employees to more easily refill the tool with rivets. They used scrap metal from their school’s metal shop and a skateboard truck to develop the prototype.

The students’ second challenge was to create an innovative solution for attaching tubes that feed electronic components to high-speed printed circuit board equipment. The students designed a unique 3D-printed fixture to attach to the feeders, enabling different size tubes to be held in place and reducing vibration. They used SOLIDWORKS® software during the design stage and collaborated with Intervala engineers on specific measurements needed for the tube formats.

Intervala engineering and production teams judged the students’ approaches to be innovative and cost-effective and to have the potential to be implemented with some additional modifications.

Thank you to Pittsburgh-based Catalyst Connection for sponsoring this tremendous program. Intervala is proud to participate and help inspire young innovators to develop game-changing intelligent solutions in the future.